CHALLENGE

Our customer produces a range of AC LED modules for lamp manufacturers. The products were originally built with discrete components, a different set for each module type. For performance enhancement and simplification of production and supply chain, the customer was looking for a custom ASIC solution. The customer was also expecting improved performance on TRIAC-Dimmer compatibility. With just a few external components (rectifier, fuse and surge) all module types may be produced using the same high-voltage ASIC type, provided that is programmable. LED modules with such an ASIC are directly driven from the AC mains voltage, are low-cost and are very compact and reliable.

TIME

In 3 weeks we realized a discrete prototype demonstrator proving dimmer compatability. Another 3 weeks later we came to an IC definition, IC process selection and proposed a design and development plan.

SOLUTION

A set of TRIAC dimmers was investigated by SystematIC for their interaction with the customer’s existing discrete AC LED product. SystematIC design methodologies were used to develop a discrete electronic solution that made the customer AC LED lamp compatible with many TRIAC-based dimmers. The discrete electronics where chosen such that they could be implemented in a HV IC process. A discrete prototype was build and demonstrated to the customer just a few weeks after first contact. This successful demonstration was the first step of the feasibility phase that followed. In that phase the IC architecture and feature set were defined in cooperation with the customer and a suitable high-voltage process, chip architecture and chip area estimation were proposed. SystematIC was selected as development partner and detailed IC design and ASIC development and industrialization followed in close interaction with the customer.

WE ARE PROUD ..

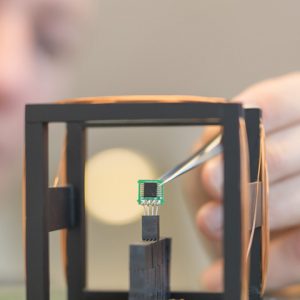

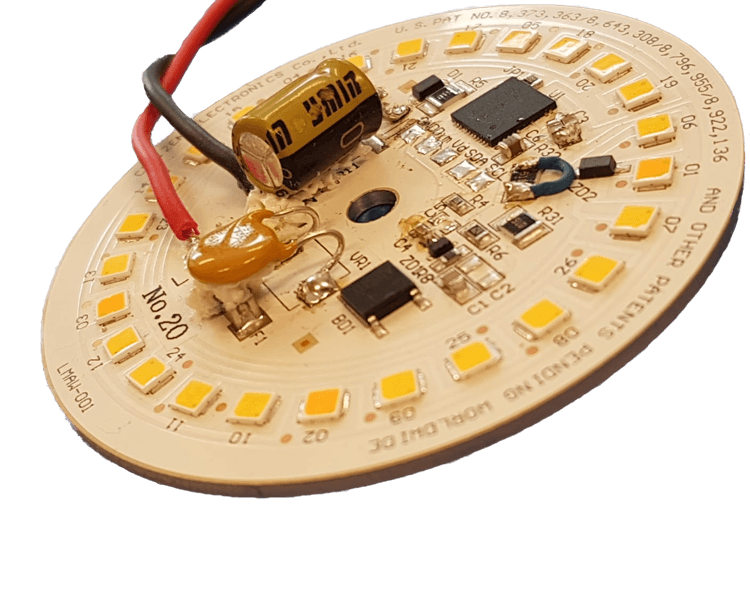

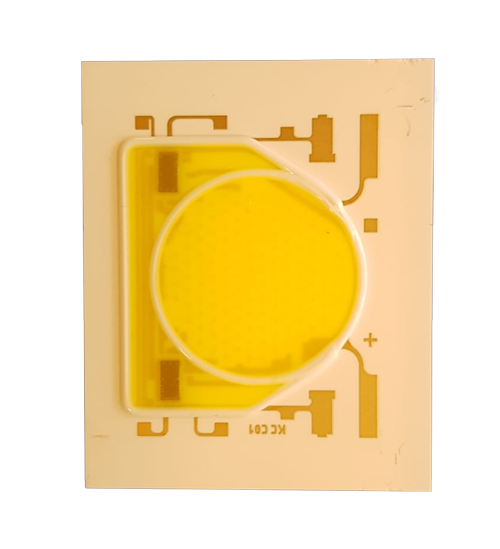

.. of our development of an innovative TRIAC-dimmer compatibility circuit, our successful design of an AC LED product using a very high voltage IC process, and our succesful industrialization of the product in two versions. The TQFN assembled version is surface mounted on LED board modules (coaster size). The gold-plated bare die version is bonded directly onto ceramic LED modules in a very small form factor (stamp size). Both tested wafer and packaged in tape-on-reel delivery are supported.

BENEFITS FOR CUSTOMER

The custom ASIC development and industrialization process was entirely handled by SystematIC, including development of wafer test, assembly with custom (HV) leadframe and final test. Thus the customer avoided risk and gained valuable time. We developed a programmable device that can support various product LED module lines of the customer using the same ASIC (a few W to 20W power range).

The customer’s supply and production chain was simplified while enhanced performance, more flexibility and additional features were realized.

KEY TECHNICAL STATISTICS

- -40 ⁰C to 125 ⁰C ambient, 150 ⁰C junction

- Direct rectified mains supplied

- 400 V / 200 mA programmable branches (700 V max)

- Single IC drives 3 LED strings

- Dual IC solution to support up to 6 branches

- Programmable TC and OTP protections

- Flexibel Analog DIM control

- Compatible to TRIAC dimmers

- Auxilary supply output

- I2C interface

OUR OTHER SUCCESS STORIES

Successful achievement of your company’s goals will require IC solutions that are tailor made for your business needs. SystematIC was founded to help businesses imagine, plan, and develop these IC solutions.