CHALLENGE

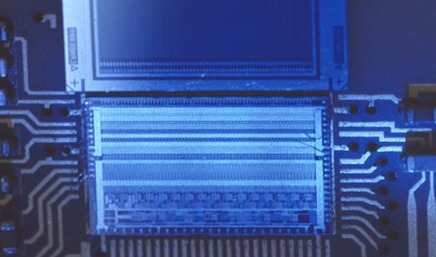

The customer has a leading international position in industrial X-ray crystallography systems. In one of these products a multi-channel HV passive XRAY sensor is applied for material analysis and an accurately matched channel readout and signal processing ASIC is required. With further signal processing is in the digital domain, digital switching should not affect the very low analog signal integrity.

SOLUTION

SystematIC proposed an architecture of ultra-low noise front ends that are noise optimized to the sensor element and applied in a matched channel configuration. Instead of typical standard CMOS, the digital electronics where designed in the form of special CML logic to obtain low crosstalk.

TIME

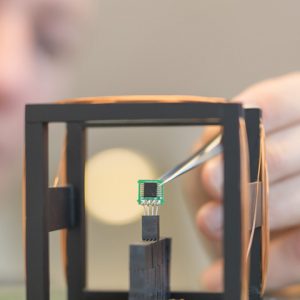

In 20 weeks SystematIC has developed a prototype IC.

WE ARE PROUD

Initially the project was supported by a competing IC design house who failed on the job. SystematIC design methodologies resulted in a first-time-right prototype and production part.

Work on the project supported the customer’s patent application US2002053641 (A1).

After a decade the IC process was no longer available for high performance mixed signal ASIC and a migration to a 0.35um process was successfully done.

BENEFITS FOR CUSTOMER

The ASIC is an essential part of the machine, the function was impossible to implement with discrete electronics due to dimensions (size) and channel matching (performance).

KEY TECHNICAL STATISTICS

- Ultra-low noise level (120 electrons)

- 128 matched analog sensor channels

- Special Digital CML interface (low cross talk)

- Qubic-1 BiCMOS and 0.35um CMOS process

OUR OTHER SUCCESS STORIES

Successful achievement of your company’s goals will require IC solutions that are tailor made for your business needs. SystematIC was founded to help businesses imagine, plan, and develop these IC solutions.