Custom ASIC Design

SystematIC , as its name suggests, draws its strength from a systematic development methodology and a profound knowledgebase which it applies to practical implementation of every analog and mixed signal ASIC it develops. Thanks to the ‘SystematIC’ methodologies, a fully functional, on-spec first silicon is attainable with minimum number of design iterations and significantly reduced overall development cost and time-to-market.

ASIC Turnkey solutions

In addition to the development and validation of prototypes on silicon, Systematic provides full supply chain management of customer specific IC products. Although operations are subcontracted, Systematic holds the unique responsibility of the entire supply chain - from order to delivery on time at customers’ preferred manufacturing site. This turnkey approach has optimized cost of mass-production solutions for several customers.

SYSTEMATIC WILL PROVIDE YOU WITH A FAST, HONEST AND OPTIMAL IC SOLUTION

We deliver qualified devices our customers can use directly in their application. These designs often pose specific requirements which are hard to realize with standard components. Factors can be low power, low noise, low cost, small footprint, high bandwidth, high voltage, odd form factors and also IP protection. Many of these factors are achieved by a high integration level on a chip. To meet commercial and technical requirements, our IC architects work closely with our customers to define system- and ASIC specification.

Proof that it is the optimal solution

We have a world-class track record in high voltage and power sensor technology and advanced signal processing.

First time functional

Understanding model accuracy, component mismatch and process corner variations helps to make robust circuit designs. The time and attention that we invest in the first design is until now in most cases rewarded with fully functional first silicon.

Fast delivery

Time to market is an extremely important aspect in many electronic developments. The best strategy is getting the most out of the first silicon. The risk in a second run, if needed, should be minimal. Therefore it is important to acknowledge and address potential risks and uncertainties in a first IC/product design as early as possible.

NO CHALLENGE IS BIG ENOUGH FOR US

At SystematIC we are fascinated about IC design. We are persons that want to know how things work and when we actually do we love the challenge of building new things with it. And this is not based on just a lucky guess but we work in a structured way to get to a result that is optimal. You can proof that what you do is very good and ultimate. It's all about capturing what you need within the limitations of physics and mathematics and use the tools that are available to actually make it. Understanding the possibilities and challenges of integrated circuit design as well as the customer requirements is key to a successful project. That is why we are fast. In an early stage we try to capture the key questions and solve these on high level.

SystematIC is a recognised partner in ASIC development and supply for industry 4.0, covering projects in process automation, preventive maintenance and wearout detection. SystematIC creates the chip architecture from sensor-in to digital-out. The analog sensor signals are processed in the analog and digital domain and interface with a microprocessor.

EXPLORE OUR CHALLENGES AND SOLUTIONS IN THE CONSUMER ELECTRONICS

Customers across the industrial sector use SystematiC within their IC and System developments to create a wide variety of next-generation of products from advanced process monitoring solutions to complex control and measurement systems. SystematIC's design and development services coupled with our IP and supply services can accelerate your time to market and reduce the risks of developing complex industrial solutions.

Sensor interfacing

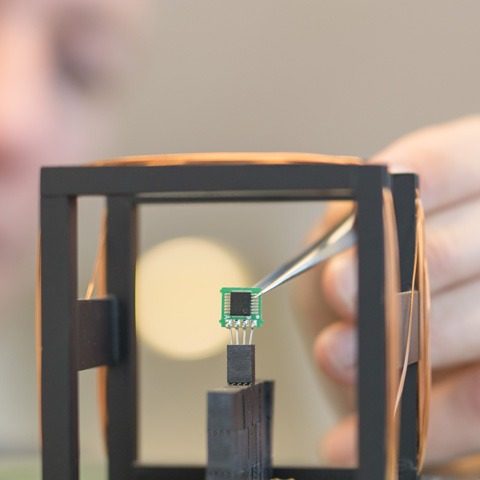

INTEGRATED MAGNETIC SENSOR

![]() 8 weeks : Design start to prototype silicon

8 weeks : Design start to prototype silicon

Our customers is the Isolation Products Division of a semiconductor leader, who has a strong portfolio based on optical isolation techniques. Application of this fully integrated single chip magnetic sensor opened a new line of magnetic isolation products. Based on our reference high speed magnetic design in 2 months’ time a 180nm CMOS prototype was shipped.

Integrated power

POINT-OF-LOAD POWER CONTROLLER

![]() 4 weeks : architecture and IC design proposal

4 weeks : architecture and IC design proposal

Our customer, a fabless semiconductor company, started a new product line of drivers and controllers for power converter applications in industrial applications. SystematIC took care of the design of a complex power controller IC targeting application in Point-of-Load Power Modules, used in Ethernet Routers and Switches and other Industrial Applications. The customer’s approach was to offer a very versatile IC to the market that also realized excellent performance parameters (efficiency, ripple, etc). The customer discovered a strong market interest and had marketing & sales and application support in place but lacked the IC design resources for a quick product development. Within a year SystematIC developed all accurate analog functions in a new IC process and delivered the verified mixed-signal chip design and layout.

Sensor interfacing

X-RAY DETECTOR READOUT

![]() 20 weeks: prototype IC

20 weeks: prototype IC

The customer has a leading international position in industrial X-ray crystallography systems. In one of these products a multi-channel HV passive X-ray sensor is applied for material analysis and an accurate matched channel readout and signal processing ASIC is required. SystematIC proposed an architecture of ultra-low noise front ends that are noise optimized to the sensor element and applied in a matched channel configuration. The digital electronics where designed as special CMOS CML logic to obtain low crosstalk.

25

YEARS IN BUSINESS

with clients across the globe

85%

RETURNING CLIENTS

approach us for their next IC development

50+

PRODUCTS IN MASS PRODUCTION

to improve your day-to-day life

OUR LOYAL CLIENTS

We are very proud. 85% of the organisations we work for have given us multiple projects. You get solid, honest IC solutions that meets your requirements and business objectives.

TELL US ABOUT YOUR PROJECT

If you have any remarks or questions regarding our products or our services, please fill in the form or contact us by e-mail or by phone.

SystematIC (HQ)

Elektronicaweg 20

2628 XG Delft

The Netherlands

Phone: +31 15 2511100

E-mail: contact@systematic.nl