CHALLENGE

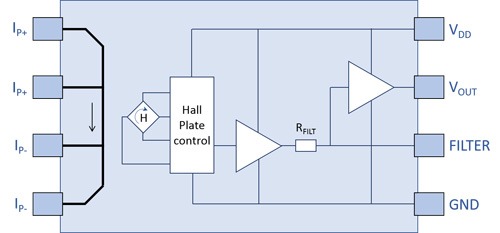

Our customer is a diversified global semiconductor leader. Their Isolation Products Division has a strong portfolio based on optical isolation techniques. Application of fully integrated single chip magnetic sensor opens a new line of magnetic isolation products to the customer with technical and commercial benefits.

SOLUTION

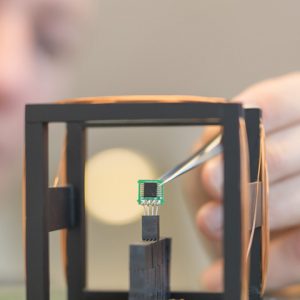

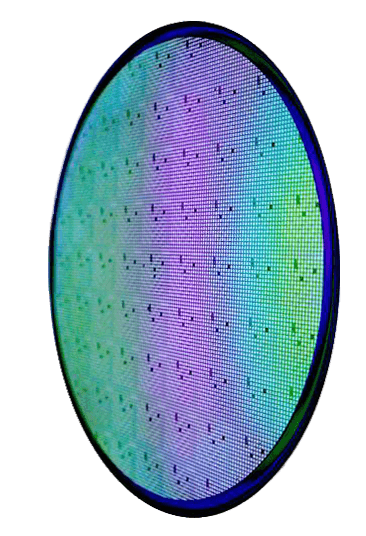

Based on our reference high speed linear magnetic design in 2 months’ time a custom180nm CMOS prototype was shipped to the customer. The customer had real silicon to examine and test their isolated assembly. During the next phase, the core technology was extended with customer specific features and resulted in an optimized ASIC. Along with the delivery of the wafers, SystematIC’s experienced development team supported the customer with definition and implementation of wafer test and final test.

TIME

In 8 weeks we have developed and shipped prototype silicon.

WE ARE PROUD

To support the customer with the industrialization of this magnetic product in a short development time. To successfully reach mass production and support the customer to further roll out the technology.

BENEFITS FOR CUSTOMER

Access to proven isolation technology in a short development time.

- Wide Operating Temperature: –40⁰C to 110⁰C

- Sensing current range: ±10A to ±30A

- Output sensitivity: 66 to 185 mV/A

- Single supply operation: 5.0V

- Device bandwidth: 80 kHz typ

- Extremely stable output offset voltage

- Near zero magnetic hysteresis

- Typical total output error of ±1.5%

- >25 kV/μs Common-Mode Transient Immunity

- UL, CSA: Isolation Voltage 3 kVRMS, 1 minute

OUR OTHER SUCCESS STORIES

Successful achievement of your company’s goals will require IC solutions that are tailor made for your business needs. SystematIC was founded to help businesses imagine, plan, and develop these IC solutions.